“Great Drives” is a Zcarblog series highlighting scenic routes and destinations we have enjoyed from the past and present. Whether it is a nice cruise or thrilling adventure, we hope to inspire Bay Area vintage car owners to Enjoy The Ride! Have a great drive of your own that you want to share? Feel free to contact us on Facebook, Instagram or by e-mail.

Mt. Umunhum to Alice’s Restaurant, October 2018

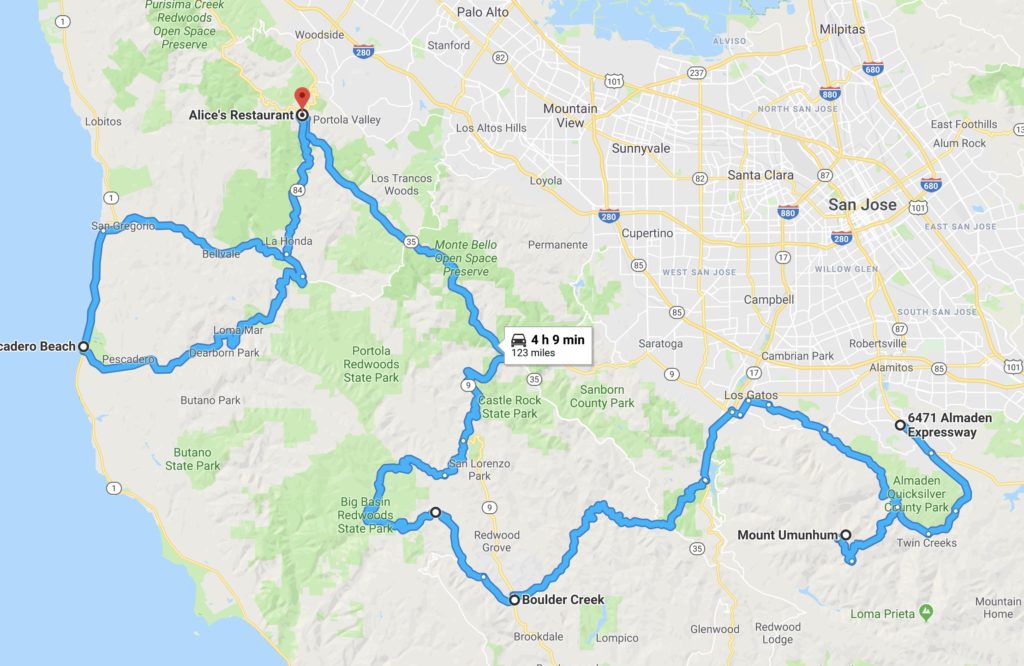

There are several fun routes reaching Alice’s from San Jose. This drive was organized by Lotus 7 owner Geoff W and we all met in Almaden to begin:

The 11-car group was diverse with both vintage and modern sports cars with great Nissan/Datsun representation!

The cars:

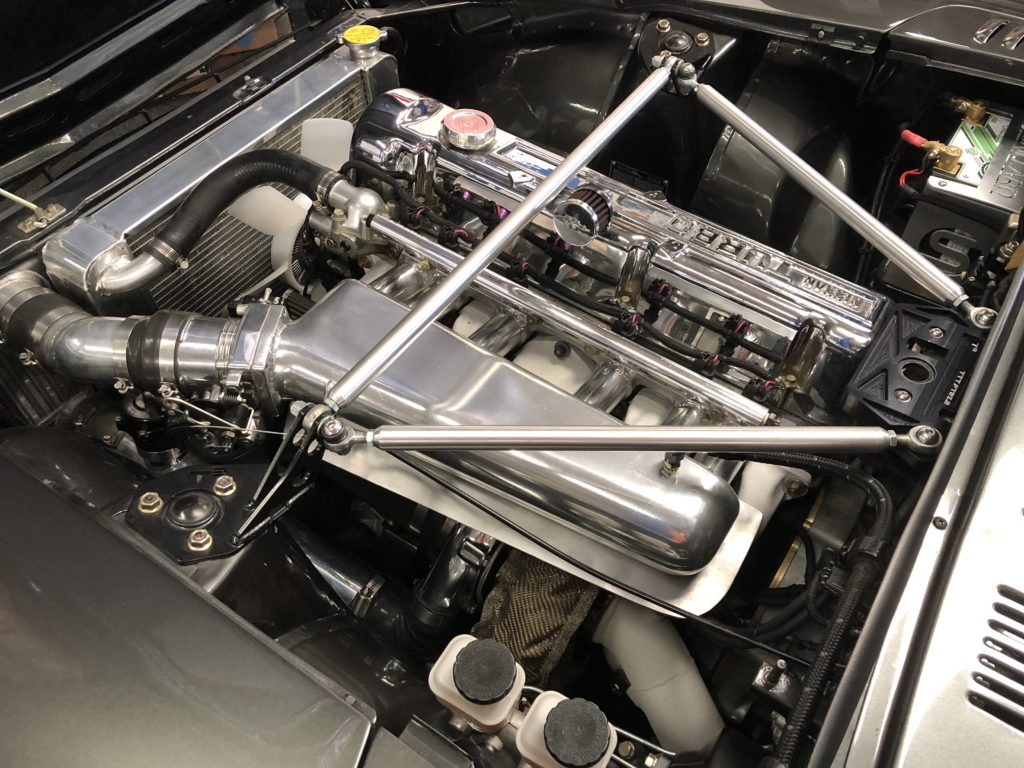

Daniel’s Nissan 240s (S13) with an RB25DET swap. He is the man behind the lens of BayRoadsAP. Naveed Yousufzai’s R32 Skyline GT-R:

Lane Skelton of DrivingWhileAwesome in his Porsche 944. Eric in the 911 Targa

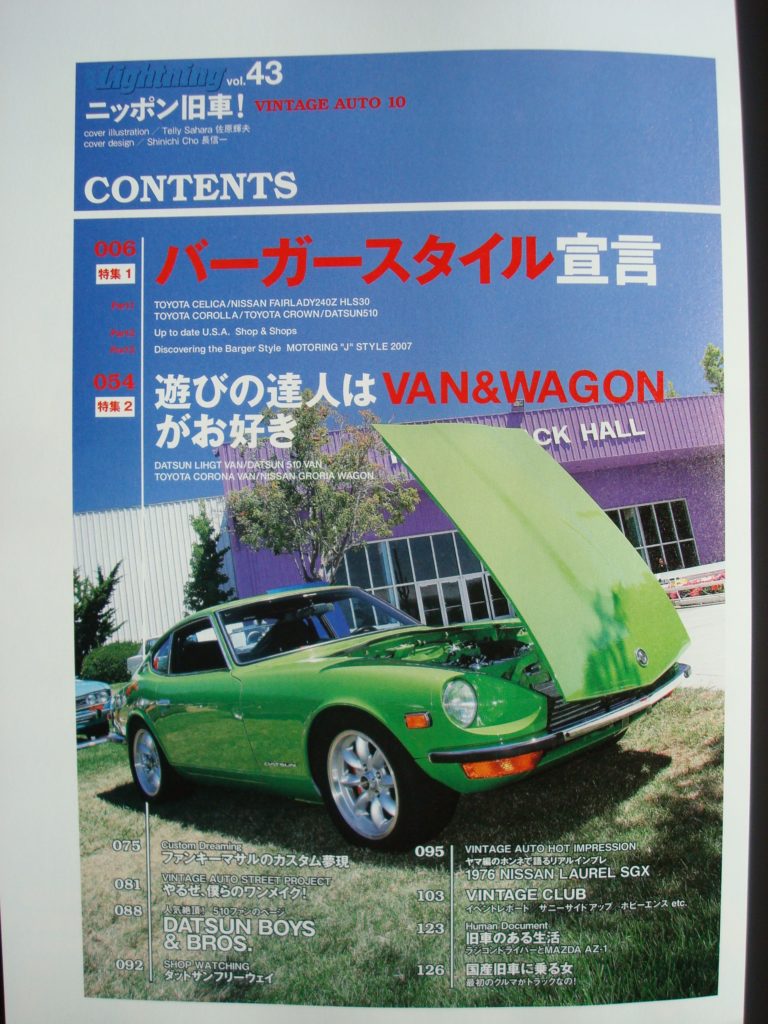

TWO Z cars! Michael’s Series 1 240z (with patina) and Andrew’s Series 1 Fairlady Z (RHD!)

Geoff (organizer) in his Lotus 7, featured on Petrolicious! Mike in his 993 Porsche:

The route:

Driving through Almaden to Mt. Umunhum:

The climb up to the peak is filled with freshly paved road and switchbacks. At the top:

In the lower lot we had a few minutes to chat and check out the cars

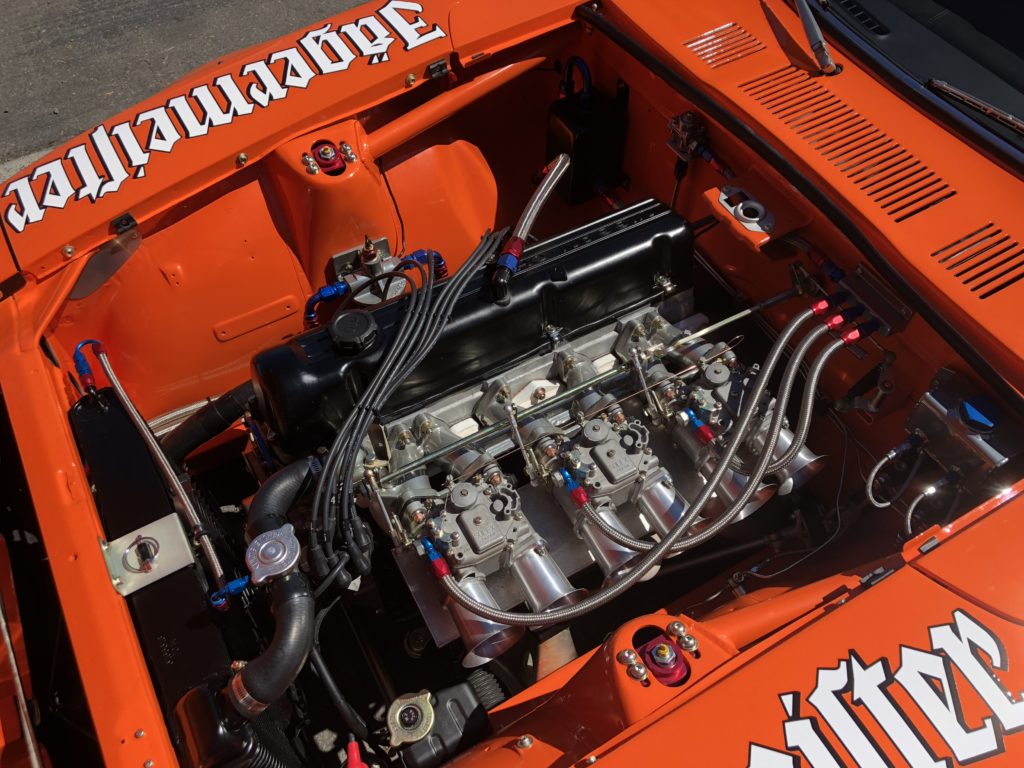

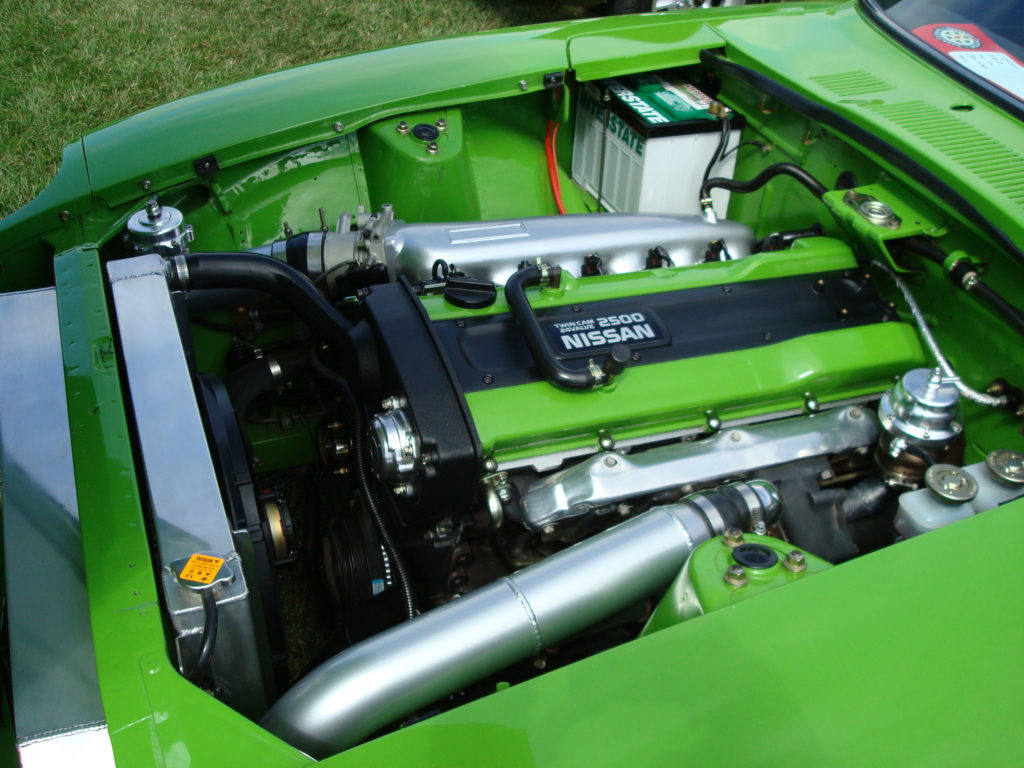

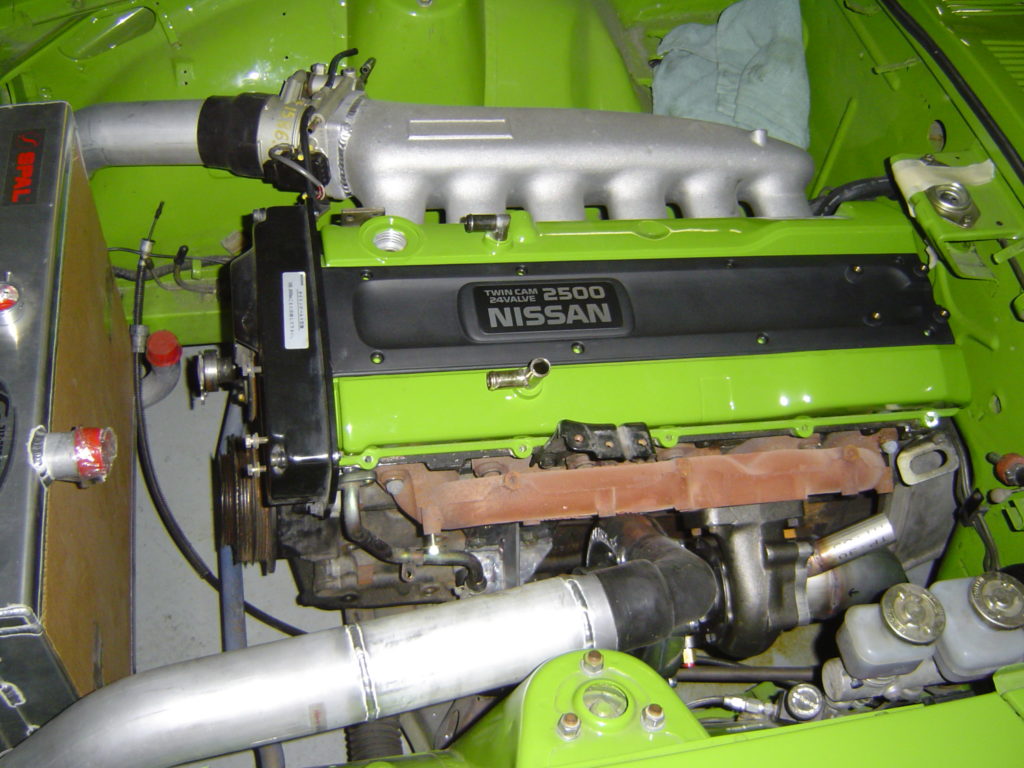

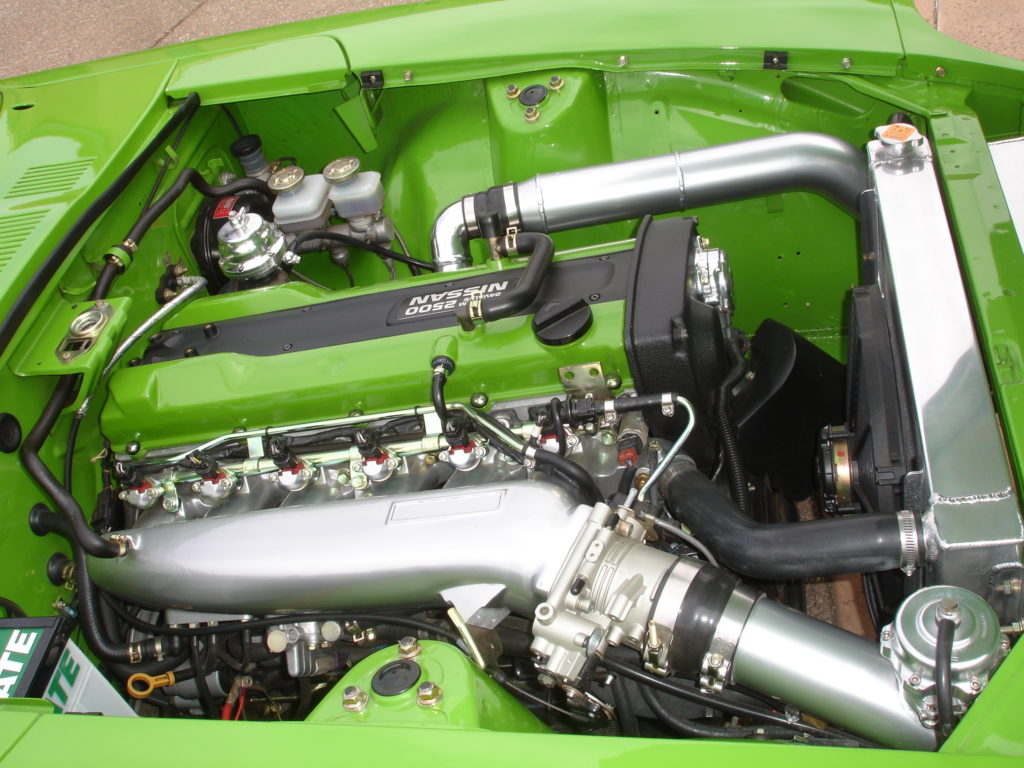

I really dig Michael’s S30, it has a warmed-over triple-carb’d L-series:

We left Mt. Umunhum towards 17 and exited on Bear Creek Rd. for lunch in Boulder Creek. This was a fun stretch I haven’t been on.

Heading up 9 to 35. It was fun chasing Michael in the Z:

We had a little scare when his oil pressure gauge started reading low….it checked it ok and we were off again:

The route changed a bit and we took Alpine Rd. (lots of loose gravel) to Pescadero Creek Rd, then Stage Rd. After re-grouping we hopped on HWY 1N:

From 1 we turned right onto 84. This stretch was amazing. SO much fun connecting the turns and chasing Geoff in the Lotus. This is a road that made me love my roadster even more. Thanks Geoff for an exhilarating drive!

All of the Roadsters at Alice’s Restaurant. An “Aero Cycle” joined:

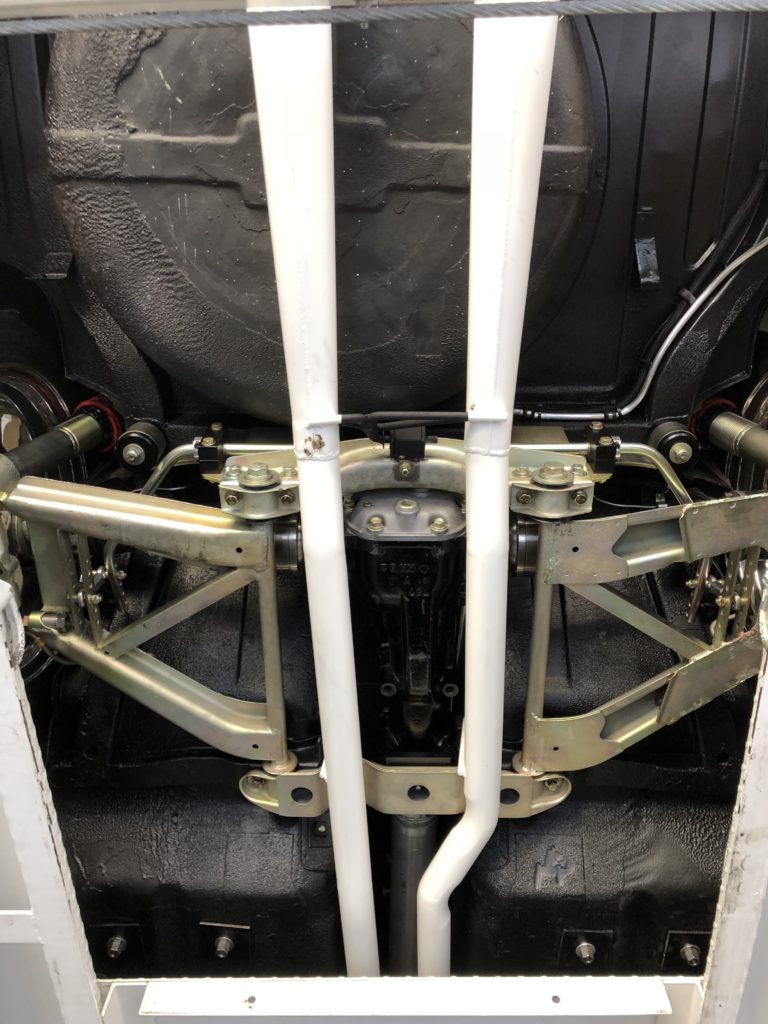

We also got a closer look at Geoff’s go-kart. One look at the driver’s seat tells all: this is a wild ride!

After drinks we departed. Alice’s never disappoints.

Here’s video I snapped showing the action, enjoy!

After drinks we split up for home, and i took 35 back down 9. I was treated to some great coastal and bay arae views:

Big thanks to Geoff for organizing the drive. It was a fantastic run with great company! More pictures in the gallery below.