We love to see owners installing our Z Car Garage CV Axles on their vintage Nissans and Datsuns. Steven added a set to his gorgeous 1972 Skyline GT-X that he performed a full restoration on in New Zealand.

Our Z Car Garage CV Axles help transmit power to the ground and ensure smoother operation compared to your standard half shafts. These are 100% bolt-in replacing your half-shafts and does not use aluminum adapters commonly found in aftermarket units. Over 250+ CV axle kits on client cars with unanimous positive feedback.

Steven shares his experience replacing the original half shafts with ZCG CV Axles on his Hakosuka Skyline…

“I decided to upgrade as my overall goal was to build one of the best Skylines in the world, having the old clunky axles wasn’t going to fit the bill. It helped to see photos on the website of Hako’s with them installed (see Ray and Julio’s Hako’s) however still nervous about how the quality would stand up to certification in New Zealand. After a lot of online research I chose on the ZCG CV Axles and rapt with the results.

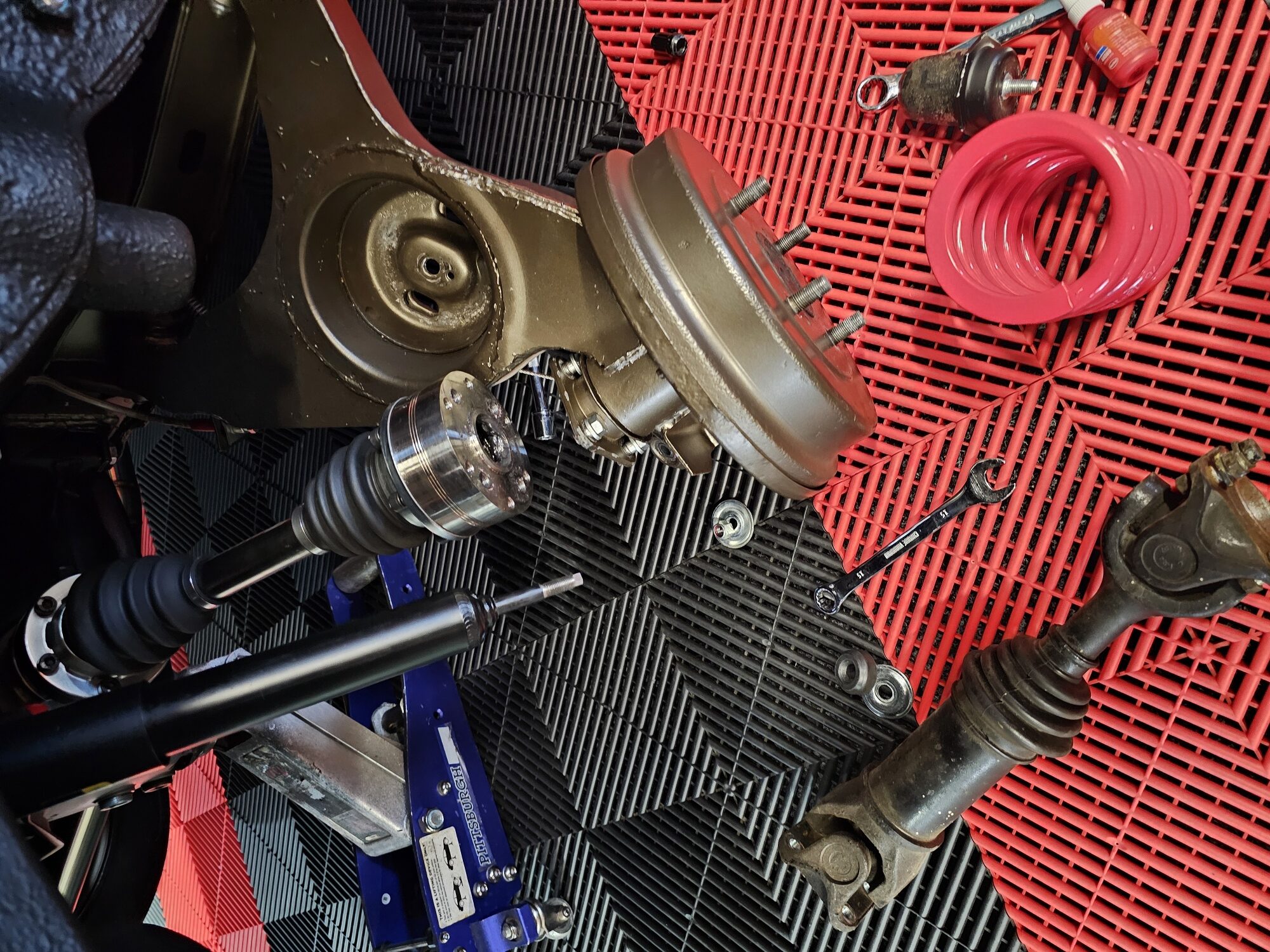

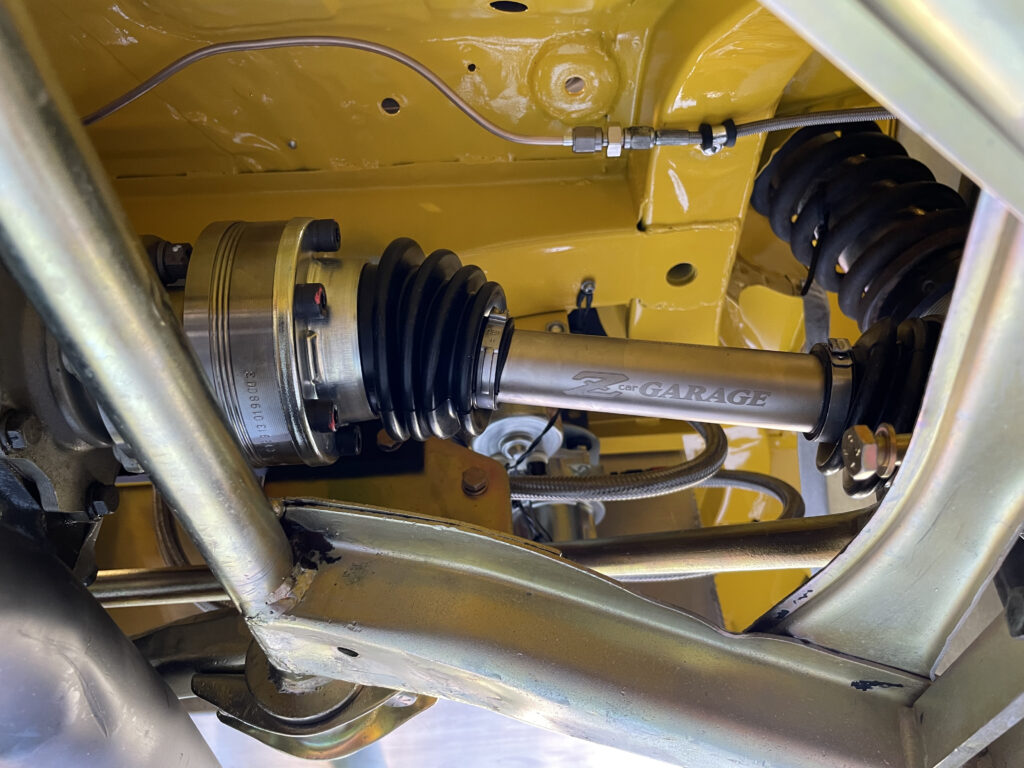

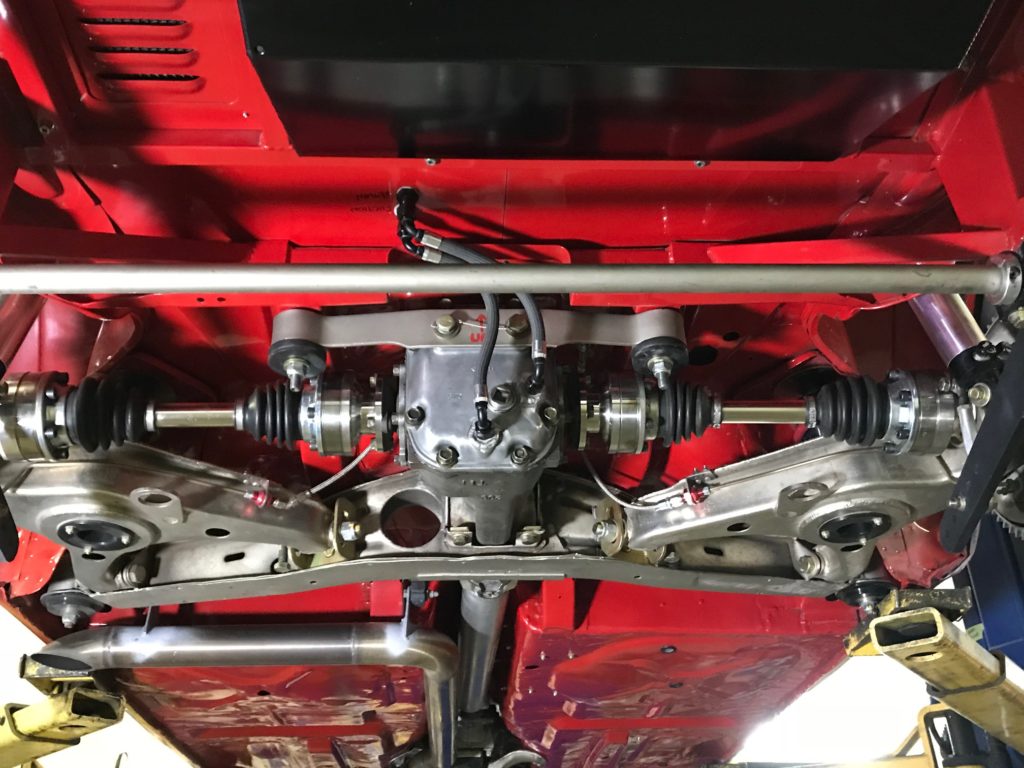

Steven kindly shared installation photos (more in the gallery below) with us:

“As always when buying stuff from half way across the world I am very nervous however the website looked great and the buying/shipping process was simple. The Axles were extremely well made and packaged, we have very tough certification rules in New Zealand however the certifier had no issues with the axles. They were as simple as undoing 4 bolts on each end of the factory axles dropping it out and putting the CV Axles in place and doing up the bolts. Absolutely no modifications and nothing more than a 14mm spanner needed.”

Super stoked to hear Steven enjoying the axles, enjoy this video of his installation:

“The noticeable benefits were noise reduction, smoothness of rear suspension movements and they look great”

Skyline Dreams

The Hakosuka Skyline is undeniably a JDM icon. We asked Steven about his history with Japanese classics and his dream to own the original Skyline…

“Life time goal starting out in 2005 with a 1998 Nissan Skyline GT (4Door) in Grey, moving onto a 1998 Nissan Skyline GTT in 2007 (2 Door) in Red, to a 1999 Nissan Skyline GTR in 2020 in white I was well down the path of getting to the dream of trading my way to own a Hakosuka. The GTR market went crazy in 2022 so I made the most of the opportunity to sell and bank the money for when I finally manage to locate the right Hakosuka as I knew I would need every cent for the rebuild. Having never been to Japan and not speaking a word of Japanese I came across Scott Palmer from Nippon2u, he was an Aussie so we could have a good yarn and he happened to have the car (1972 Nissan Skyline GT-X KGC10 13,678kms, Grade 3.5, L20, 2HT, 5 Speed) but laughed when I said I was keen on purchasing it as the prices were crazy and the rebuild costs to have it clear certification in NZ were enormous given its 50 year old thin steel.”

“These cars are the pinnacle of Japan’s motorsport history, so I knew it wasn’t going to be easy the auction was 11:56am on 7 th April 2023 and we set a price of 6,860,000 yen but that was soon passed to 6,905,000 yen and still didn’t meet the reserve. I just needed to take the leap and hope it was a solid car as with auction fees etc. it came to 8,120,000 yen…on par with the market and still cheaper than an R34 GTR in NZ. Finally on the 21 June it was on the ship with Dolphin shipping and arrived in Auckland on 6 th July, 4 months after auction. Walking into the PTS logistics office I had no idea if the car would even run or roll, the car luckily was exactly how I imaged it to be, original/solid but needing a good restoration.”

The Restoration

Steven’s goal for the restoration was to build the car utilizing best in the world components.

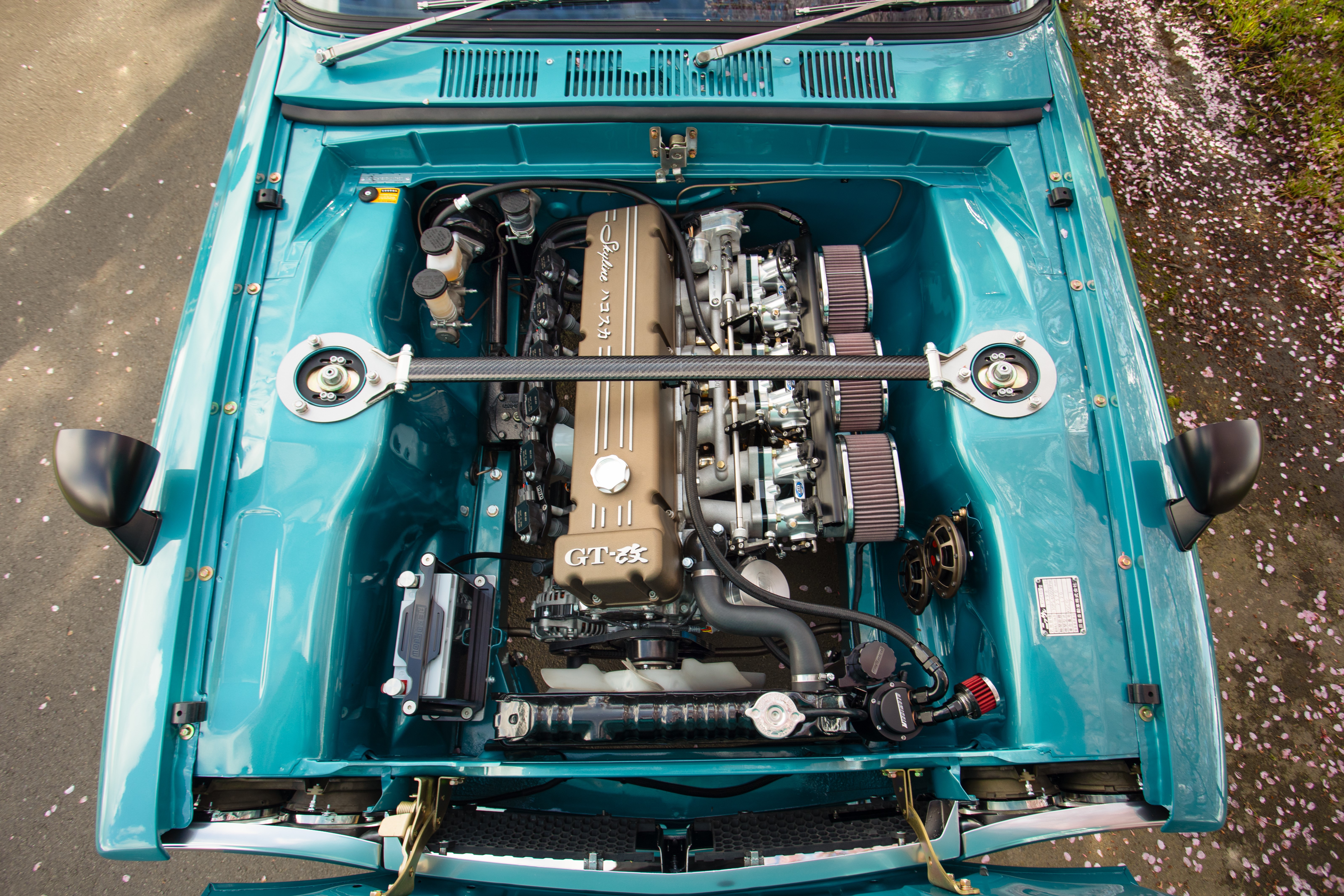

“Even before it arrived in New Zealand I had developed a project plan with what I deem the best of the best in their respective fields. I wanted to do as much as possible but also wanted to make sure we achieved the highest quality finish possible, and I think this is the high quality example of the Hakosuka in the world. I stripped the car down to a bare shell within days and started restoring everything whilst moving the body and drivetrain to the professionals. Spent hours building custom brake lines, stripping subframes, machining/pressing/customise mounts. Chris Calder of Waipukarau long term friend and in my opinion the best painter in the country. Full bare metal, rotisserie strip down and paint job which included the cutting and flaring of rear guards, complete replacement rear panel and unstitching a lot of the panels to treat. Smoothing of engine bay, removal of body holes for aerial and front bonnet centre trim. The car was also fully sealed underneath.”

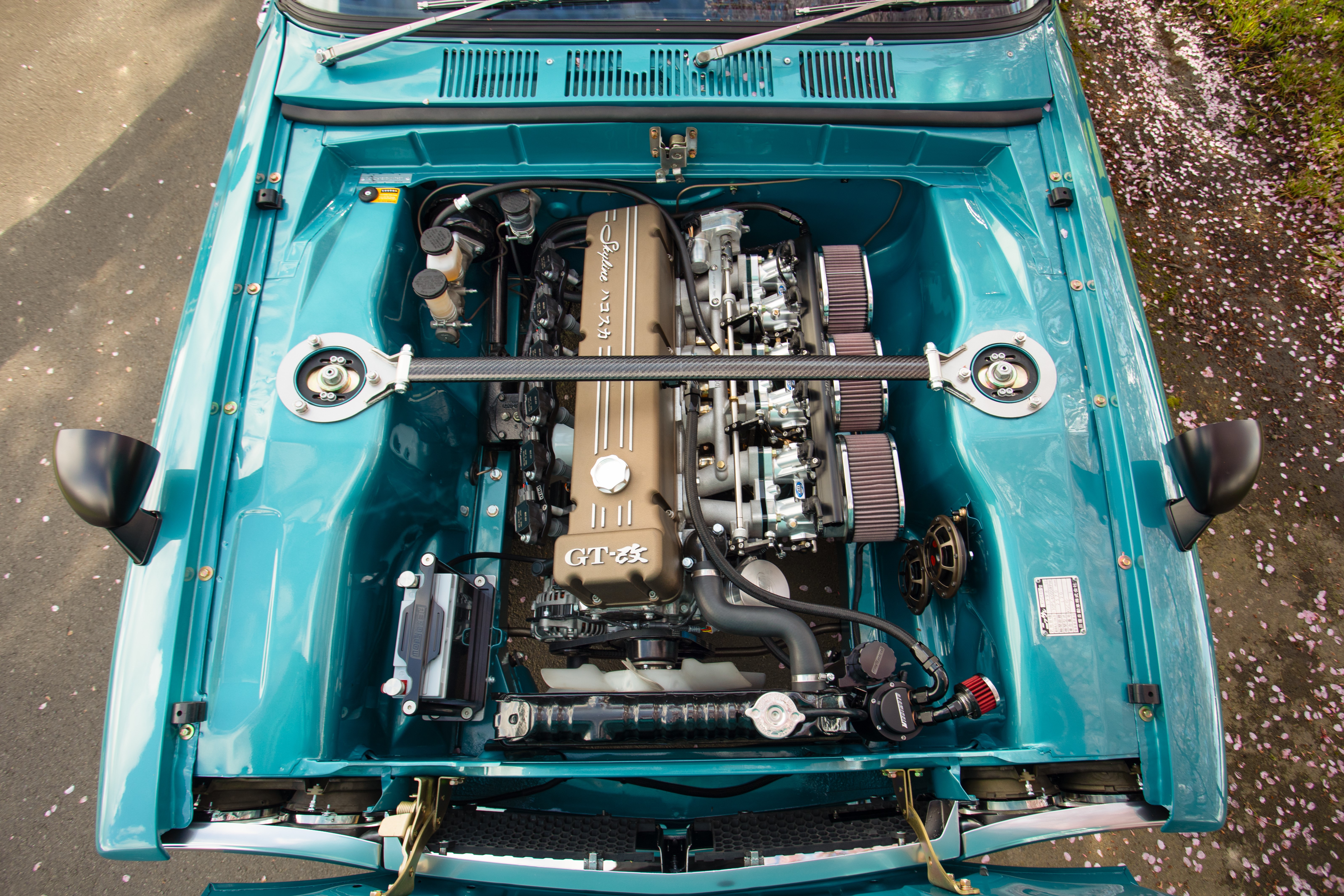

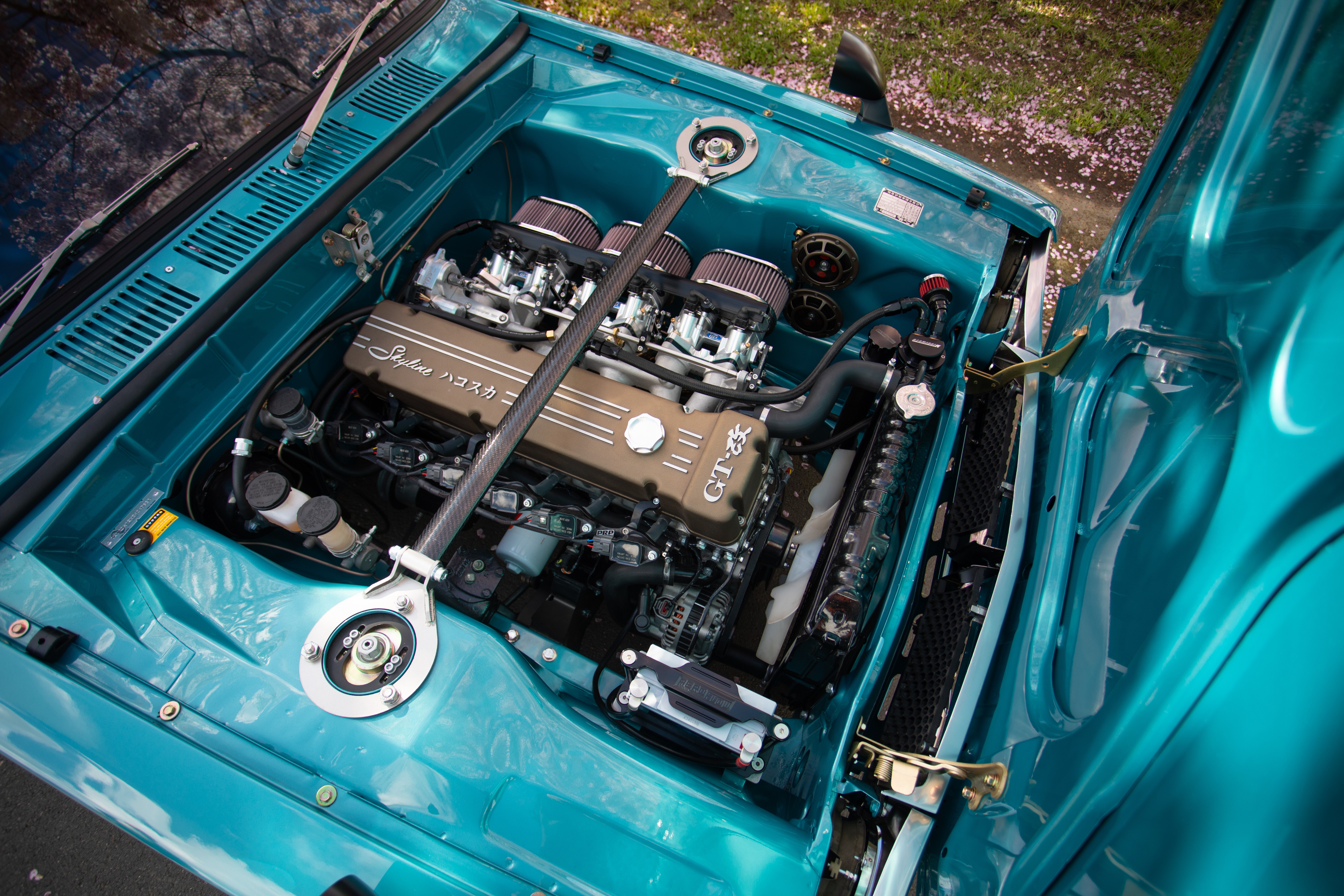

“Engine was removed and sent to PPRE in Whanganui which they were keen to get their hands into as a change from their normal rotary engine building. Gareth was given a bit of a free licence to make the engine the best it can…”

– Haltech Nexus R3 and PD16 Computers

– Nissan r35 GTR Coils

– Ported and Polished Cylinder Head and Manifold

– Fully custom built stainless steel headers and exhaust

– Custom build in tank fuel system

– L20 2L Engine, 141hp at the wheels

– EFI Hardware full ITB kit, fuel injection system, inlet manifold with Billet distributor

and sensors and electronic accelerator.

“Rear CV axles we sourced and imported from Rob Fuller @zcargarage in the San Jos California and fitted perfectly. Front adjustable suspension was built by Evan @ Speedfactor in Tauranga, they were able to build a coil over system which bolted in directly along with all of the necessary reports for certification.”

“Bede Stevenson at bspeed engineering custom built the engine rocker cover Along the way I had a few great mates that helped with guidance as they are at the top of their field especially Isaac Probert and the team at Manawatu Auto Electrical. They completely re wired the car from scratch which involved some technical programming of the two Haltech computers as well as an incredible attention to detail. This included me having the opportunity to build the front wiring loom alongside Isaac and learn a few new skills along the way. Then a massive list of parts were sourced through FNLHVN.com in Japan, the owner Jamel is awesome. This was one of Chris Pocock’s final jobs as the owner of Classic Custom Motor Trimmers, he has spent decades building custom upholstery and he was determine to take on this complete re trim. I took it upon myself to build the centre console from scratch to better modernise the driving experience.”

“Aidan at Pine Engineering in Wakefield (South Island) was able to customise a set of genuine Watanabe 3-piece wheels to my specifications to get as much rubber on the road as possible. This was a great option for difficult wheel sizes and offsets The tyres and rims were a massive challenge however Jared Parker from Zestino Tyres in Wellington was keen to get involved and supplied the 195/50/15 and 245/45/15 ZS01’s. Every nut, bolt and bracket on the car has been either replaced with new or I have stripped down and had it powder coated by Glen @ Elite Powder coaters in Palmerston North, also any bare metal fittings we gold anodised in Palmerston North by Graham @ electroplating Manawatu.”

After a 14-month long journey, Steven has some final thoughts on the restoration:

“I have been very fortunate to have had the ability to build American, British/Aussie and now Japanese cars and I can say hands down the Japanese definitely made life a lot easier with their design and materials. This included everything fitting perfectly, metric!!!!, having the foresight for electric windows, air conditioning and even adding threaded mounts for 3 point seatbelts from and rear even though they only came with lap belts. Weight is only 840kgs, independent rear end, HANDbrake, and perfectly fitting straight 6 motor. This car has been built to drive so once it has done the car show scene it will be seen out on the road and around the odd track cruze event. I have recently managed to blow up my challengers motor so that’s the next project.”

Steven has been Enjoying the Ride in his dream car Hakosuka Skyline. What’s next? He’s got a mint set of Recaro seats to match his interior and he’s trying to source a complete replacement set of window glass for the car and store the factory glass. We are confident he’ll score a set of make his own 🙂

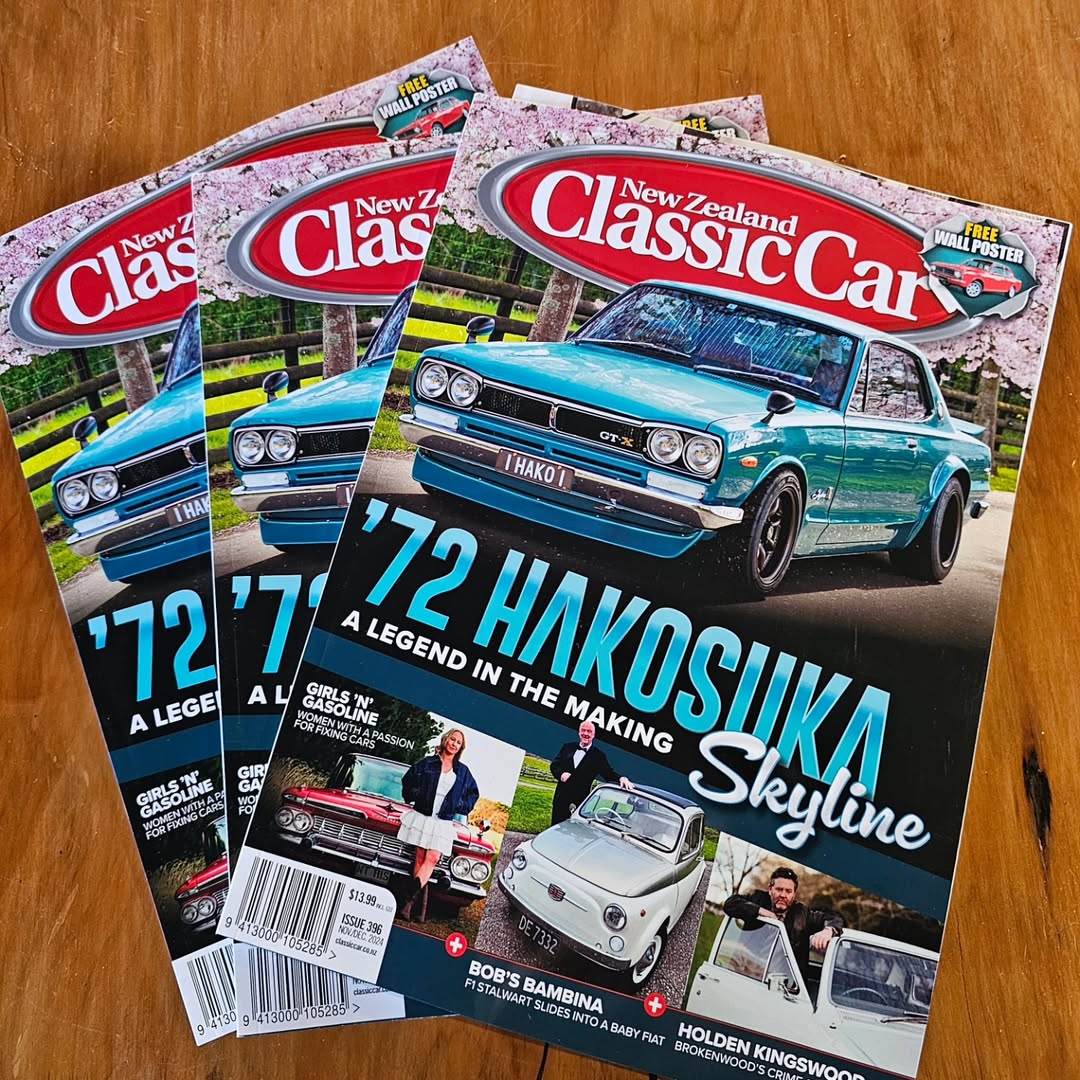

Back in October the Hako was featured in New Zealand Classic Car magazine and he’s been driving everywhere, as it should be! You can follow his adventures on Instagram

Thank you for your support Steven, your Skyline is amazing! Please read below for more information on our ZCG CV Axles:

ZCG CV Axles

Our Z Car Garage CV Axles help transmit power to the ground and ensure smoother operation compared to your standard half shafts. These are 100% bolt-in replacing your half-shafts and does not use aluminum adapters commonly found in aftermarket units. We have over 250+ CV axle kits on customer cars and we are stoked with all of the positive feedback.

For years we have used aftermarket CV axles that utilize an aluminum adapter prone to loosening up over time. Despite efforts to keep things tight (Loctite, hardware changes) we had to keep an eye on them. We developed a better solution that eliminates the need for aluminum adapters and remains 100% bolt-in like a factory half-shaft.

Designed and manufactured locally with KAD Models, the ZCG CV axle kit works in both R180 and R200 configurations.

These are the beefiest CV axles on the market. They have been tested on the track by our vintage racing customers and also in high hp* street cars (powershifting, clutch dumps, etc.). Each axle has a serial # for peace of mind:

The CV axle kit is available now from ZCG for 1595.00 + freight and they come with everything you need to install on your car. Contact us at 408-452-0350 or send Rob an e-mail rob@zcargarage.com to purchase. Installation is just like doing a half-shaft: there is even a marking that shows you where to line up bolts and special hardware:

The ZCG CV Axles in action

The video below demonstrates the “looseness” associated with aftermarket CV axles that use adapters compared to the ZCG axles without adapters. Several customer race/street cars running our CV axles are also shown. Enjoy!

Enjoy this video made by our client Hazel. She installed our ZCG CV Axles on her Hazel’s 1970 Datsun 240Z

Over 200 sets of our ZCG CV Axles are installed in client’s cars all over the world:

Supermachine in Tokyo, Japan is running our Z Car Garage Big-Brakes and Z Car Garage CV Axles in their Series Datsun 240Z:

Race car driver, restorer and Datsun Historian Glenn Chiou is running our ZCG CV Axles in this IMSA GTU 260z race car!

Elmo’s 1972 Datsun 240Z is running our Z Car Garage Big-Brakes and Z Car Garage CV Axles

Racer Brad H is running ZCG CV Axles in his IMSA GTU race car:

Race car driver and restoration specialist Jim Froula of Racecraft is running ZCG axles in several of his cars:

Set #246 – installed May 2018 on the “Harry Stewart #52” Datsun 510:

Set #247 – installed April 2018 on the 260z

Set #248 – installed on Adam Carolla’s “Greg Sorrentino #90” Datsun 510.

Related Articles

No user responded in this post