At Z Car Garage we love dyno tuning vintage race cars that are being brought back to life in addition to event veterans. Stan T came up from Socal on referral from fellow racer Steve Link to get his Datsun 1200 back on the race track.

The Datsun 1200

A few words on the 1200 for the uninitiated, as this small but feisty little Datsun surprised many. The car was Nissan chassis code B110, sold in Japan 1970-1972 and in North America in 1971-1973. Known in the states as a “1200” from its 1.2L engine size and referred to as “Datsun Sunny 1200” in Japan, The 1200 had a rich racing history with success both here and abroad with much of it prowess coming from a lightweight chassis and potent A12 powerplant.

Les Cannaday’s 1971 Datsun 1200, during Saturday practice. 2013 Coronado Speed Festival © 2013 Victor Varela

Stan bought his Datsun about 10 years ago as a barn find, tired SCCA H Production racecar. The SCCA logbook that came with the car showed only two races ever entered. It was mostly stock, with a bolt-in Autopower roll cage. Stan tells us about his build and desire to build it with period parts wherever possible:

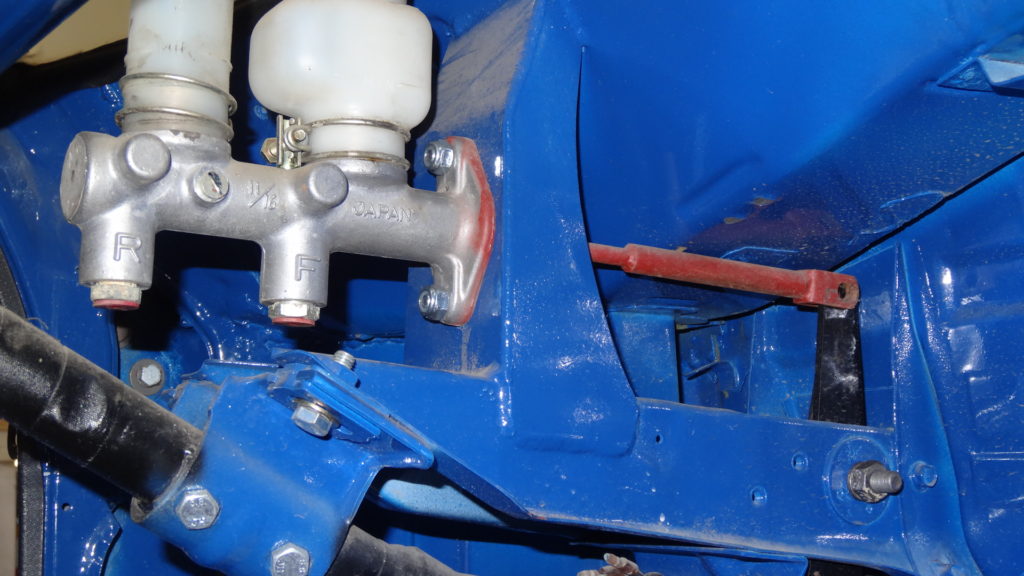

“Back in the day, one could literally build a Datsun 1200 racecar out of the pages of the Datsun Competition parts catalog. Everything from engines to gearboxes to LSD rear ends was available. Factory teams and independents flocked to the Datsun nameplate, using the available go-fast bits and pieces. My thought with this project was to build up a tribute car in the vein of the original SCCA C Sedan class cars from the 70s, using parts from the Datsun Competition catalog as much as possible. No later, larger engine. No bigger rear axle. Everything was to be as close to period as possible, everything was to be restored with an eye towards authenticity and durability. No Tilton or Wilwood braking systems…I re-fabricated the braking system using historical pictures as a reference.”

“I’ve searched for several years gathering bits here and there from around the world. It was a tedious process – racers naturally use up parts, parts which were not plentiful to start with, and the stockpiles of available pieces had grown smaller over the years. The F5C56A close ratio 5-speed transmission came from New Zealand. A quick shifter and some engine parts came from Japan. Reproduction tail lamp housing gaskets came from a fellow 1200 enthusiast in the Pacific Northwest.”

What about that cool two-piece rocker cover?

“The one-off alloy rocker cover was CNC milled by a genius 1200 owner who took pity on my plea for a two piece unit that would make valve clearance adjustments considerably easier in the pits and back at the shop.”

Race prep advice came from retired 1200 racers who provided a treasure trove of knowledge. The engine was built by master machinist John Edwards in Costa Mesa who, when he was an automotive shop teacher, persuaded Nissan to donate dozens of the A12 engines to the school district for training purposes.

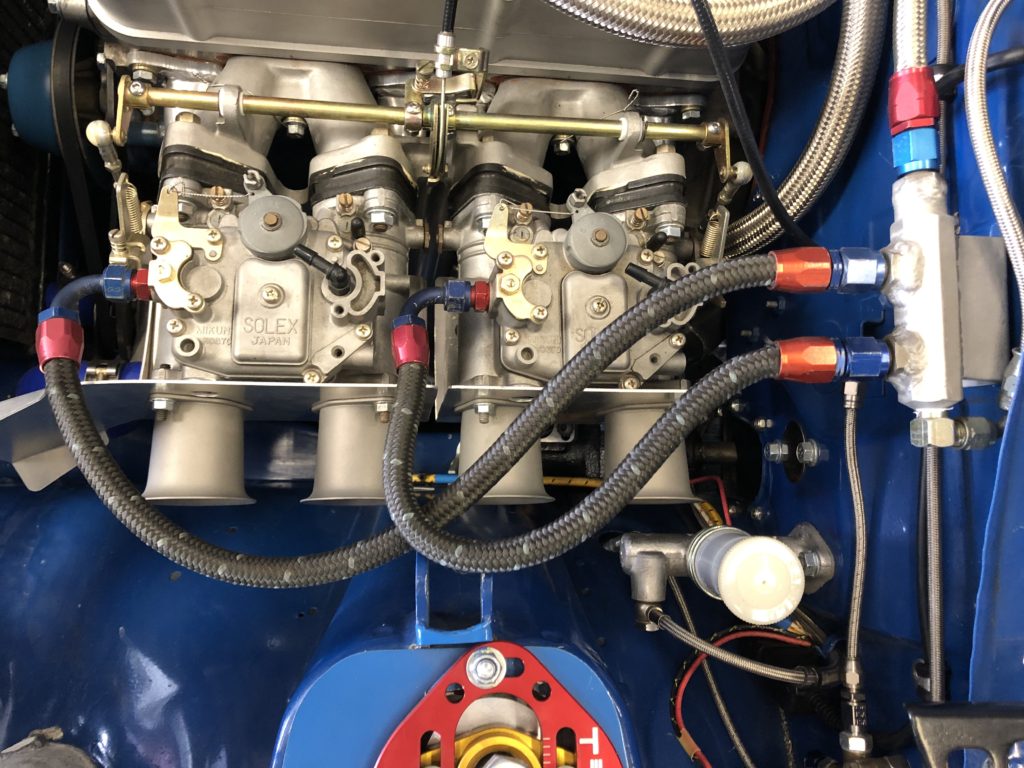

“This engine is an old SCCA warhorse that was run for years in the San Francisco region. The engine features a ported GX head and a slew of NLA Nismo bits along with trick “modern” pieces like ARP head studs & rod bolts and B-Projects rocker arm collars. It is being resurrected for vintage racing, using a bit more moderate state of tune for longevity and reliability. (if 12.8:1 compression can be called “moderate”)”

Below is a video showing Stan’s A12 motor on the R&D SimTester. It has a variable speed electric motor connected to the flywheel end of the crankshaft, spinning the motor. An oil line connected to the inlet side of the oil pump pressure feeds clean oil to the engine. The tester allows a ‘clean room’ run in of the freshly built engine to bed all the assemblies in, check for oil leaks, find weak/stripped bolts, ascertain clearances of rotating bits at various speeds etc. without generating heat and racket:

Stan adds the final steps of his build before dyno tuning:

“Final assembly and fabrication was done by Vinny Torres at Steve Link Racing in Anaheim. While the parts chase was going on, I stripped the body down to a bare shell and had it soda blasted back to bare metal, then repainted it the way it was when I bought it. During that phase, heavy rust was discovered in the cowl area which demanded attention, and after the heavy undercoating was stripped off, it was found out that the front clip of the car had been replaced at some point in an amateurish fashion, requiring a trip to the body shop alignment table to tug things back into some semblance of square.”

Dyno Tuning

With the car on the dyno Rob and Josh went to work checking things over in the engine bay. They set the timing correctly, worked on the A/F ratio and fixed a few items in the engine bay.

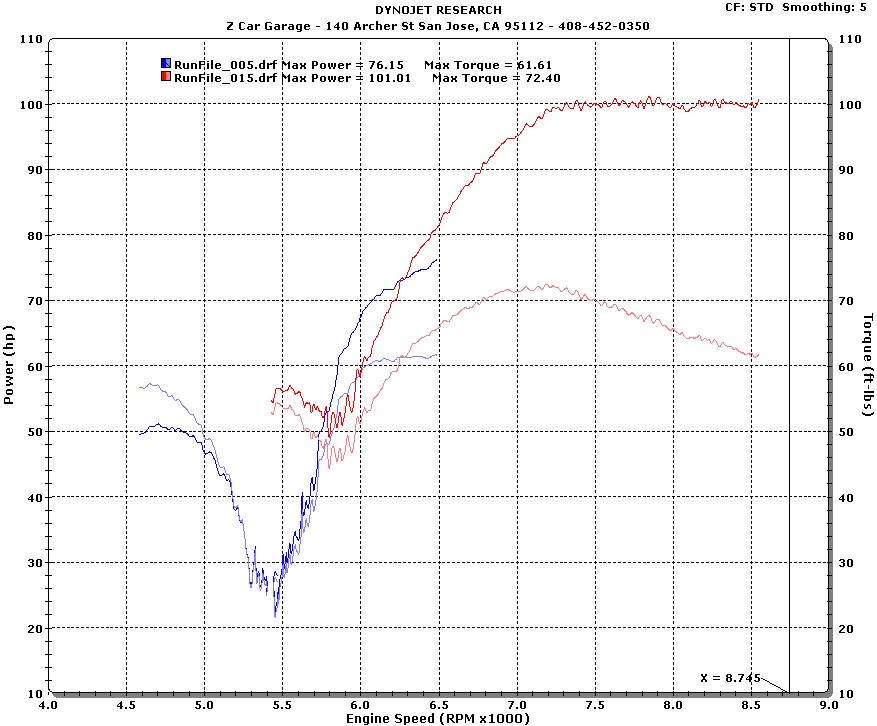

The car made fantastic power screaming to 8500rpm:

It was a win/win and Stan was more than pleased:

“1st dyno run (blue) showing how poorly the engine ran when I brought it in, then the last dyno run (red) showing the Helen Keller Miracle Worker version, where at the end of that run we all high-fived each other and shouted “Done!” Watching Rob & Josh work together was like watching a couple of master musicians in a recording studio bouncing musical ideas off of each other, with each building on the other’s talents until all of a sudden everything clicks, and a hit is born. They make it seem almost effortless until one steps back and realizes the personal database of tuning knowledge they have has been amassed through thousands and thousands of dyno runs and hundreds of days at the track all feeding back on each other. All the while I stood there awestruck, just happy not to get in the way and to learn a few things while watching the masters at work.”

Thank you Stan for bringing your 1200 to ZCG. We look forward to your next race!