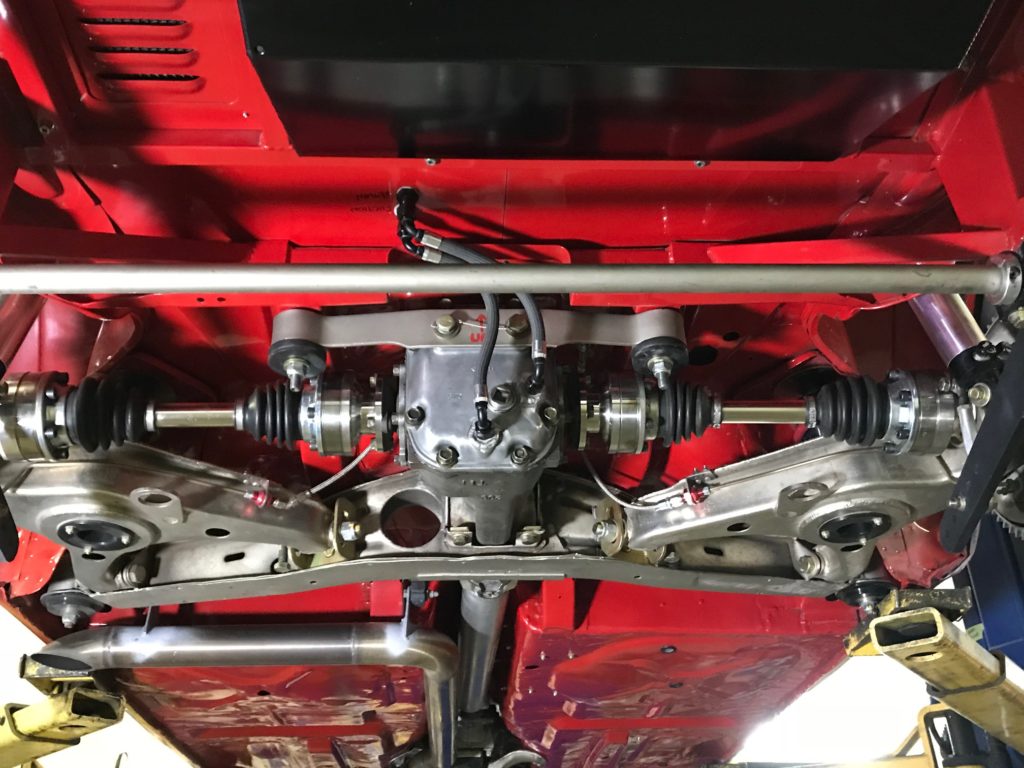

Z Car Garage is proud to offer a CV axle conversion kit for your Datsun S30 and 510. For years we have used aftermarket CV axles that utilize an aluminum adapter prone to loosening up over time. Despite efforts to keep things tight (Loctite, hardware changes) we had to keep an eye on them. We developed a better solution that eliminates the need for aluminum adapters and remains 100% bolt-in like a factory half-shaft.

Designed and manufactured locally with KAD Models, the ZCG CV axle kit works in both R180 and R200 configurations.

These are the beefiest CV axles on the market. They have been tested on the track by our vintage racing customers and also in high hp* street cars (powershifting, clutch dumps, etc.). Each axle has a serial # for peace of mind:

The CV axle kit is available now from ZCG for 1595.00 + freight and they come with everything you need to install on your car. Contact us at 408-452-0350 or send Rob an e-mail rob@zcargarage.com to purchase. Installation is just like doing a half-shaft: there is even a marking that shows you where to line up bolts and special hardware:

The ZCG CV Axles in action

The video below demonstrates the “looseness” associated with aftermarket CV axles that use adapters compared to the ZCG axles without adapters. Several customer race/street cars running our CV axles are also shown. Enjoy!

S30 and 510s running the ZCG CV axles

Randy Jaffe’s #46 BRE Datsun 240z received the very first set of ZCG CV axles: Serial # S30-000240!

The Bluebird SSS Coupe and Hakosuka Skyline are both running ZCG CV axles on the race track:

Race car driver and restoration specialist Jim Froula of Racecraft is running ZCG axles in several of his cars:

Set #246 – installed May 2018 on the “Harry Stewart #52” Datsun 510:

Set #247 – installed April 2018 on the 260z

Set #248 – will be installed on Adam Carolla’s “Greg Sorrentino #90” Datsun 510. We are pleased to report that Jim will also be installing a set on his “George Alderman #32” 300ZX! The ZCG CV axles are also perfect for high hp street cars. The following customer cars are all running our CV axles now:

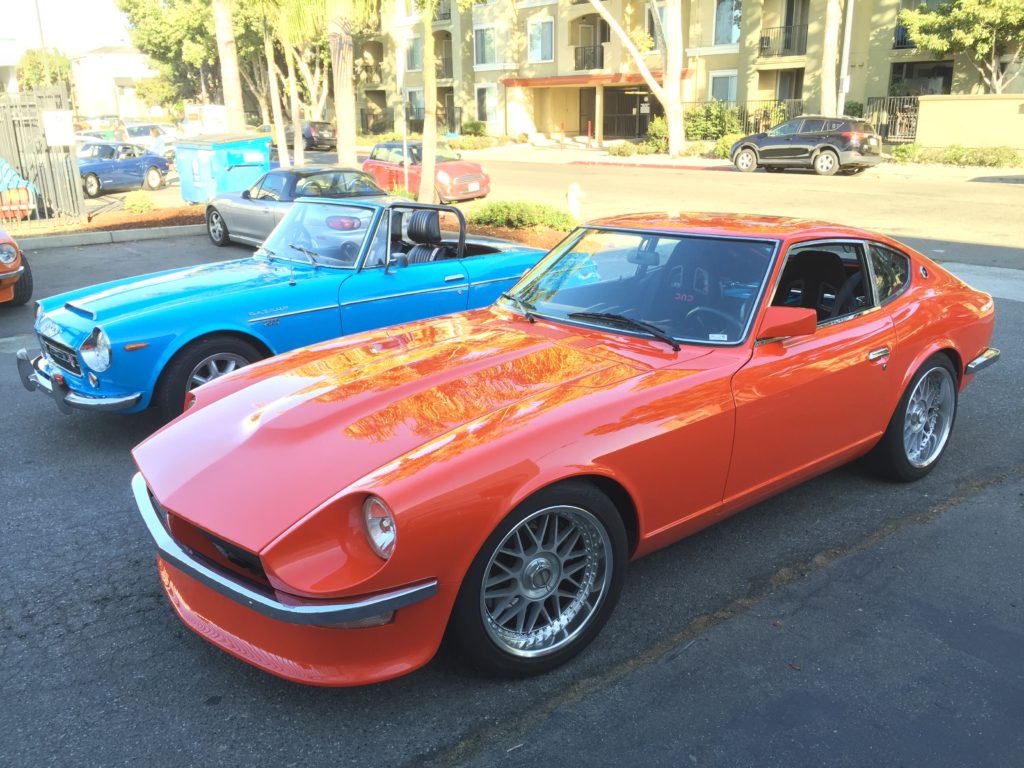

Frank B’s fuel-injected, 6-speed stroker L-series:

Gary’s 430whp LS3-powered 280z:

Scott W’s EFI stroker L-series:

James S’ L28ET:

Finally, Gary’s “Behemoth” OS Giken TC24B1Z powered S30:

Technical Information:

The Z Car Garage axles were designed to help remove much of the backlash aka clunk seen in many older vehicles. Modern technology has given us the ability to create a set of axles to exacting standards. We started with a high quality set of CV joints that were found to be the most consistent in both major and minor spline diameters. We then began to design the axle itself to share the same tight tolerances. We are holding a +/- .01mm diametric tolerance on both the inner and outer spline diameters. This gives us the feeling of direct connection between differential and wheel. The axle shaft major diameter was increased to 28MM to give owners a bit of added comfort in knowing the main shafts are stout. Once the axles are splined they are then heat treated to obtain the desired harness. After heat treat the axles are then nickel plated to add corrosion resistance. The inner and outer flanges are made from 316 stainless steel and mate to the CV joints with tapered alignment surfaces to ensure concentricity is maintained throughout the axle thus reducing vibration. The inner flange attaches to the stock R series differential utilizing the Nissan factory hardware. The outer flange attaches to the driven stub with bolts specifically designed and manufactured for the Z Car Garage axle installation kit. These bolts are manufactured to grade 8. All ZCG axles are manufactured locally which helps us maintain the fitment and quality we require.

Materials

Axles : Hardened AISI/SAE 4340 Alloy Steel, 4340 is a nickel-chromium-molybdenum alloy steel

Drive flanges: 316 stainless steel, Type 316 steel is an austenitic chromium-nickel stainless steel

Outer Flange Bolts: Hardened 4140 Alloy Steel , AISI or SAE 4130 grade is a low-alloy steel containing chromium and molybdenum as strengthening agents

Related Articles

No user responded in this post